Devoted to the powder process area

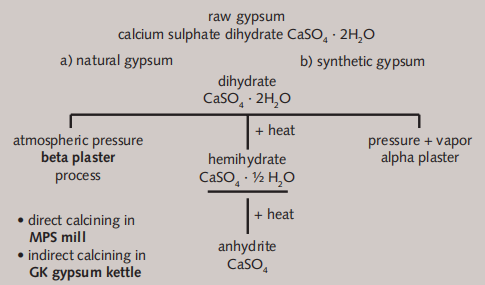

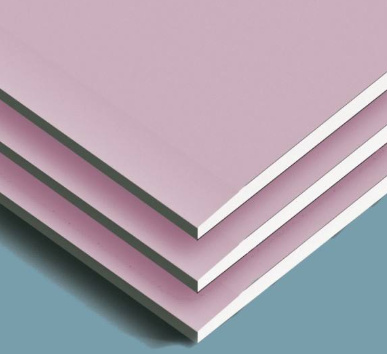

Gypsum is a white to gray mineral found in the earth’s crust. Its properties and products of gypsum to be used as building material in construction works are discussed such as the plaster of paris, gypsum board, wallboard, cement etc. What is more it is known as "satin spar" and "alabaster" are used for a variety of ornamental purposes.

With the development and progress of gypsum industry, the need of gypsum powder is growing, also with the quality of gypsum powder. During the whole procedure, the drying and dehydration are the key link, and it is also the difficult part. According to such a condition, after many years researching and exploring, we have developed a new generation dehydration device which are suitable for all kinds of gypsum production demand boiling furnace.

Two different modifications of the hemihydrate CaSO4 x ½ H2O are produced

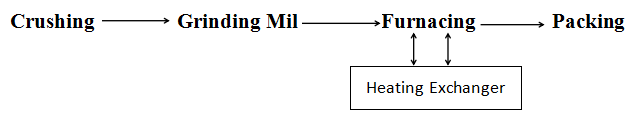

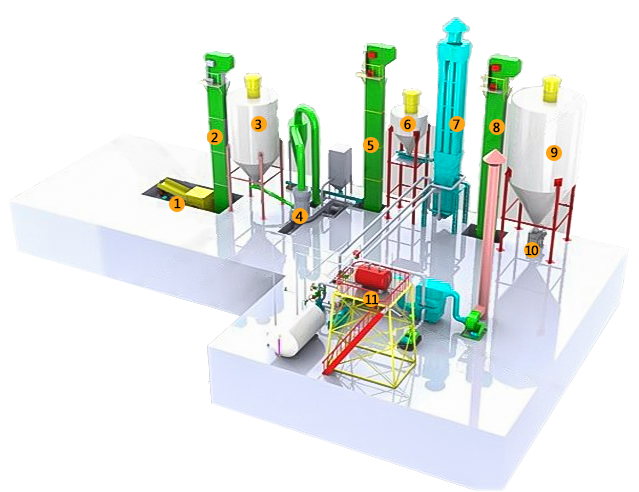

The nature gypsum ore is crushed into small particles(under 15mm), then send into the raw material silo by the No.1 bucket elevator.

By the vibrating feeder, the gypsum granular are fed into roller mill to grind into 100-200 mesh powder. Then flow into the transit(buffered) silo by the No.2 bucket elevator.

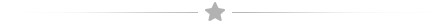

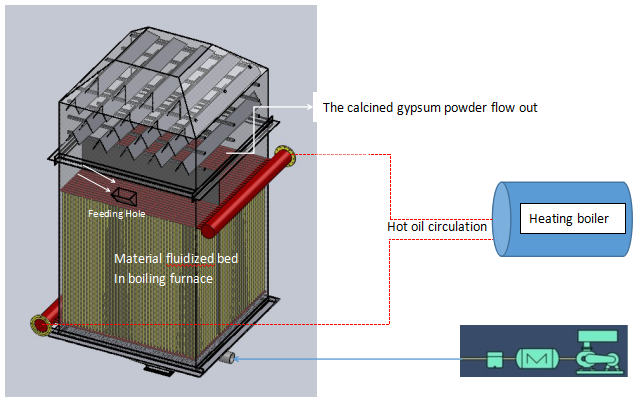

With the dosing screw conveyor the gypsum powder is fed into furnace boiler and reaches the material bed area. The roots blower under the kettle blows the air into furnace to let the gypsum powder into boiling statue. There are many coil pipes in the materials bed area, the heat conductive oil is circulated in the tubes, release the heat into the inside of furnace. Under a certain temperature, the dried and dehydrated powder become light, and flow to the outlet automatically. There is the dust catcher to collect the dust and air at the roof of kettle, to make sure the boiling gypsum powder in the balance condition.

After the calcining progress, the qualified powder will flow out to the No.3 bucket elevator. By the lifting, the powder is transported into the final powder silo. After the temperature decrease down, the calcined gypsum powder is packed into 25kg or 1 tons jumbo bags.

Such as the 10 t/h, the outline dimension is 2*2*5m.

The furnace don’t has the running part. And due to the low-temperature source, the furnace does not have any risk of being burnt in any condition.

The feeding size, air flow speed, heating temperature can be controlled.

The heat oil tube and pipes temperature is uniform, heat transmission directly to powder.

Adopting the low temperature heat source, avoid the over-head situation, the anhydrite (CaSO4) content under 5%.

The calcined gypsum qualtiy is equal to or exceeded the requirement of the national 《calcined gypsum》standard.

Main content: semi-hydrated gypsum content: ≥80% dihydrate gypsum content: ﹤5% Soluble anhydrous gypsum: ﹤5% adjustable

The initial setting time:3~8min adjustable

The final setting time: 6~15min adjustable

Standard consistency:78~85% adjustable